Sustainability To assess the sustainability of a concept or material, it can be evaluated using…

The Importance of Weight in Electric Campvervan Conversions

The Importance of Weight in Electric Campervan Conversions – and How to Reduce It

If you’re researching electric van conversions or planning your own camper build, there’s one factor that has a bigger impact on range than almost anything else: weight. Electric vans keep improving with bigger batteries, better motors, faster charging, but once you add a full camper interior, those gains can disappear quickly. Every extra kilo costs range, efficiency, and performance.

How Weight Reduces Electric Van Range

Take the Ford E-Transit. From the factory it can cover roughly 200 miles on a full charge. Once converted with the addition of a plywood floor, MDF units, steel fittings, insulation, and accessories, the real-world range often drops to 100–110 miles1. That’s close to a 50% reduction, before you’ve packed passengers, water, or bikes. For long trips, that means more charging stops, waiting around and overall less freedom. It’s the opposite of what most people want from a campervan!

Why Traditional Builds Are So Heavy

Most camper conversions still use materials chosen decades ago for diesel vans: plywood, MDF, GRP sheets, aluminium linings. They’re familiar and easy to source, but they were never designed with efficiency in mind. A typical camper interior can add over 300kg in flooring and furniture alone, which directly drains battery power and payload allowance.

Lightweight Materials for Electric and Campervan Conversions

At Evolution Composites, we have developed natural-fibre composite boards and moulded components engineered to replace traditional panels in campervans, mobile workspaces, and commercial vehicles. Made in the UK from flax and hemp fibres with recycled foam cores, our panels combine strength, low weight, and sustainability. It is ideal for electric vehicle conversions that demand every mile of range, and for anyone looking to save money on their fuel bills!

Material Weight Comparison

| Material | Common Use | Density (kg/m³) | Weight per m² @ 12 mm | Relative to Evolution Board |

|---|---|---|---|---|

| Birch Plywood | Furniture, flooring | 650–700 | ~8.0 kg/m² | 2.5 × heavier |

| MDF | Wall panels, cabinets | 700–800 | ~9.0 kg/m² | 3 × heavier |

| GRP Board | External panels | 1,800–2,000 | ~22 kg/m² | 7 × heavier |

| Evolution Natural Fibre Composite Board | Walls, furniture, flooring | 150–300 | ~3.45 kg/m² | – |

Switching from birch ply to Evolution panels in an average build can save 100–150 kg, improving range by up to 20% and reducing wear on your tyres, brakes, and suspension.

Example: Lightweight Ford E-Transit Conversion

| Component | Traditional Weight | With Evolution Panels | Saving |

|---|---|---|---|

| Furniture & cupboards | 160 kg | 70 kg | –90 kg |

| Wall linings | 40 kg | 18 kg | –22 kg |

| Floor panel | 30 kg | 12 kg | –18 kg |

| Shelves & mouldings | 25 kg | 10 kg | –15 kg |

| Total Saving | — | — | ≈ 145 kg lighter |

Sustainability and Broader Benefits

It isn’t just about numbers on a spec sheet. Using renewable natural fibres and recycled cores reduces the carbon footprint of your van and supports UK supply chains. Even diesel and hybrid van builders benefit — lower fuel use, higher useful payloads, and a quieter, more efficient drive.

Key Takeaways

- Electric campervan conversions can lose up to 50% range through added weight.

- Replacing heavy panels with Evolution Composites’ lightweight natural-fibre boards can save 100–150 kg or more.

- Less weight = better range, performance, payload, and sustainability.

- UK-made materials ensure consistent quality and supply.

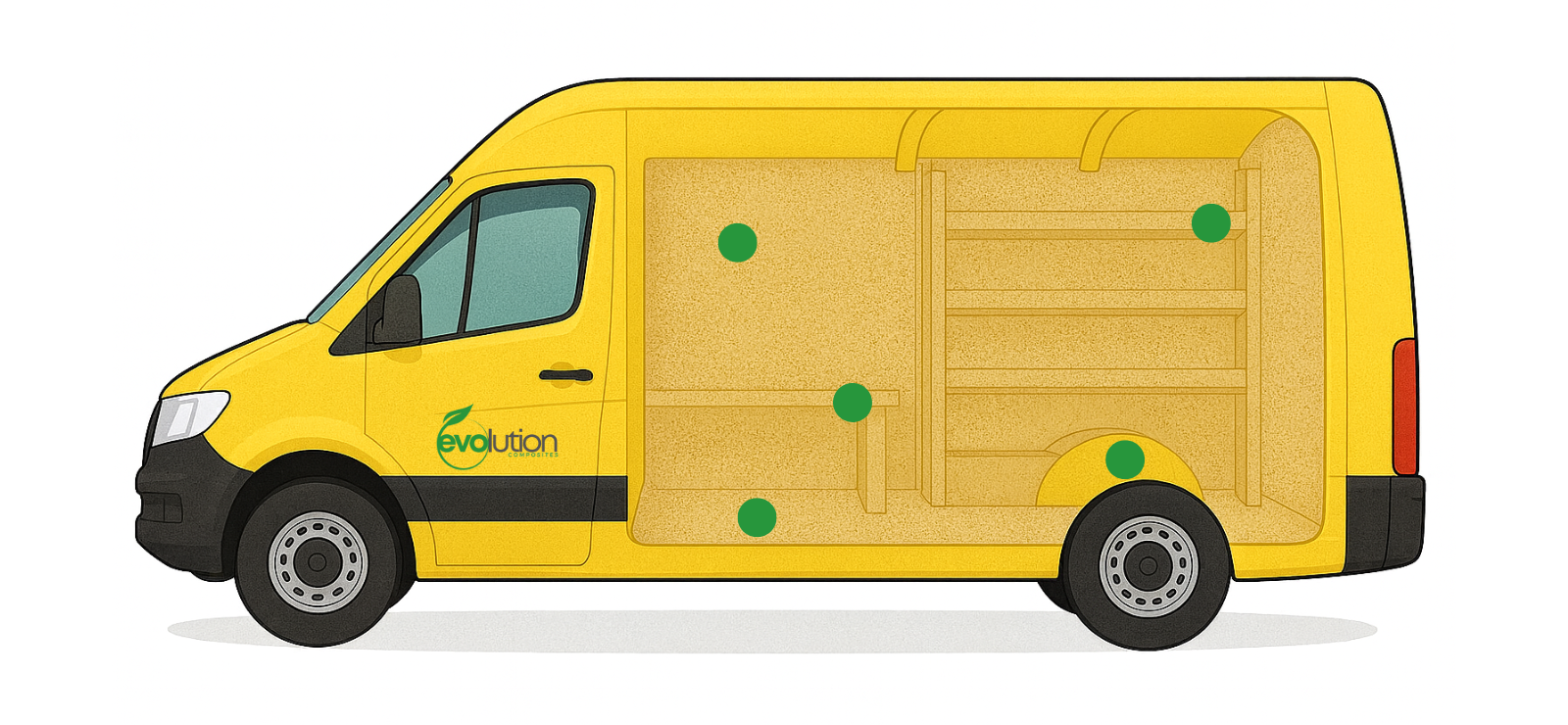

See Where You Can Save Weight in Your Van

Applications in Vans

Click the green dots to see where our materials can be used

Wheel Arch Mouldings - NatFab Form

One piece moulded natural fibre wheel arch cover produced from our bio resin based composite with recycled plastic thermal insulation pre-fitted. Offering a strong, lightweight and eco-conscious finish for your van conversion that blends in great with our wall panelling offering

Van Walls - NatFab Sheets

Natural fibre wall covers made from a single-layer composite sheet, providing a lightweight, fire-resistant and sustainable finish for van and interior wall panels. Can be used on its own or covered with other traditional wall finishes.

Van Floors - NatFab Foamo

Lightweight van flooring engineered in the UK from natural fibre composites for strength, fire safety and sustainability. Designed for rapid installation in minutes, it fully seals the vehicle floor, including any pre-existing screw holes, without screws, fillers or adhesives, creating a clean and watertight finish.

Lightweight Cabinetry - NatFab Foamo

UK-made composite cabinets built from our natural fibre panels with a recycled plastic bottle core. Each part is machined to shape and can be screwed together for precision, strength and long-term stability.

Lightweight Worktops

UK-made lightweight worktops with a durable laminate finish and recycled plastic bottle core.

Ready to Start Your Lightweight Conversion?

If you’re planning an electric campervan conversion or designing a lightweight commercial vehicle, we’d love to help. Our team can recommend the best material combinations for your project and provide samples or design support.

1 Based on the manufacturer’s mileage figures (https://www.ford.co.uk/vans-and-pickups/e-transit/van) and multiple converted van specifications (https://www.winnebago.com/all-electric , https://newatlas.com/automotive/bailey-endeavor-ev-smart-electric-camper-concept/ etc.)

This Post Has 0 Comments